Thermoresponsive Materials

Thermoresponsive Materials

Xianran Xing Professor at the University of Science and Technology Beijing, China; winner of the National Science Fund for Distinguished Young Scholars; and Changjiang (Yangtze River) Scholar

Jun Chen Professor at the University of Science and Technology Beijing, China; and winner of the National Science Fund for Distinguished Young Scholars

Kun Lin Associate Professor at the University of Science and Technology Beijing, China

【Chief members】

Xianran Xing Professor at the University of Science and Technology Beijing, China

Jun Chen Professor at the University of Science and Technology Beijing, China

Kun Lin Associate Professor at the University of Science and Technology Beijing

【Research Background】

Functional materials must be prepared and used under a certain temperature field. “Heat” can cause vibrations of atoms and electrons, which can significantly change the material properties. Thermally responsive functional materials refer to materials whose thermal response is used to achieve certain special applications, such as precision functional materials with zero expansion and thermoelectric materials, which have an important role in promoting the development of new materials related to precision instruments and aerospace. However, the thermal response mechanism still lacks a unanimous understanding, which makes material design more challenging. The research on thermally responsive materials has been accelerated by material genetic engineering research methods such as high-throughput preparation and characterization, material zero-expansion characteristics, and magnetocaloric functional materials.

【Research Objectives】

Various factors such as chemical composition, crystal structure, phonon, electronic structure, and chemical bonding can influence the performance of thermally responsive functional materials. The material genetic engineering technology will play an important role in revealing complex mechanisms and promoting new material design. The research themes are wide ranging and include exploring the ab-initio methods for theoretical prediction of the properties of thermally responsive functional materials and developing a series of high-throughput preparation methods; achieving high-throughput acquisition such as diffraction, scattering, and transmission data based on high-energy synchrotron radiation and neutron sources and other large scientific devices, to provide reliable experimental parameters for theoretical calculations and simulations; and making a significant breakthrough in the exploration of thermally responsive functional materials by developing new high-performance thermally responsive functional materials such as precision zero-expansion alloys.

【Main Research Areas】

1. Designing thermally responsive functional materials and developing high-throughput methods for their synthesis

2. High-throughput acquisition of structural information about thermally responsive functional materials based on neutron/X-ray total scattering technique

3. “Gene” research on the physical properties of thermally responsive functional materials

【Significant Research Progress】

1. Development of thermally responsive functional materials based on material genetic engineering

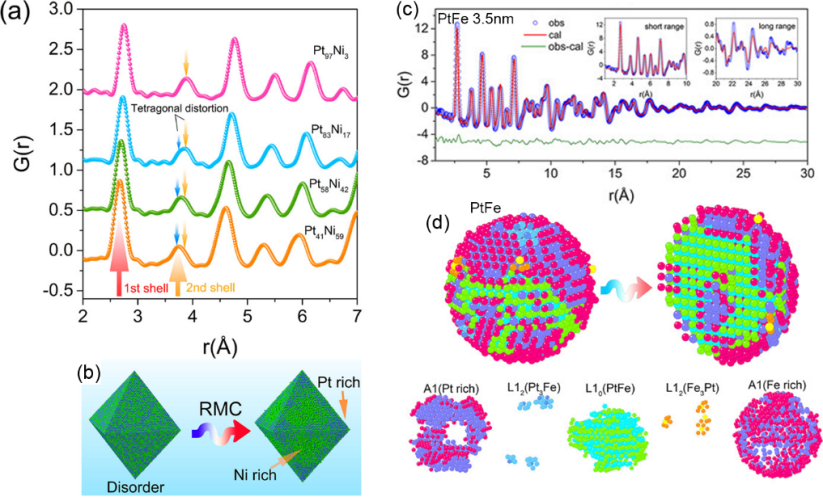

Combining X-ray absorption fine structure (XAFS), atomic pair distribution function, and the reverse Monte Carlo (RMC) method, the “genetic” association between the local chemical environment and the evolution of the thermally responsive structure in Pt-3d alloy nanomaterials were revealed from the perspective of the local structure (Fig. 1). Through the statistical distribution of chemical elements in PtNi nanoalloys, the local coordination similarity between local chemical order and long-range order of the L10 phase is linked with the lattice thermal response, and a dialectical agreement between the macroscopic lattice thermal expansion and short-range atomic pair bond expansion is found. By using the RMC method to separate the local phase and the strain parameters of nanomaterials, the interface-matching relationship between the local chemical strain and the negative thermal expansion strengthening in ordered PtFe nanomaterials is extracted, which provides an important structural model for further advancement of the artificial designing of the thermal expansion behavior of nanomaterials, thermal stress optimization of nanodevices, and the expansion of the functional physical properties of zero-expansion nanomaterials.

Fig.1 Atomic pair distribution function and reverse Monte Carlo fitting model of PtNi and PtFe alloy nanoparticles

2. A new method for material lattice strain control

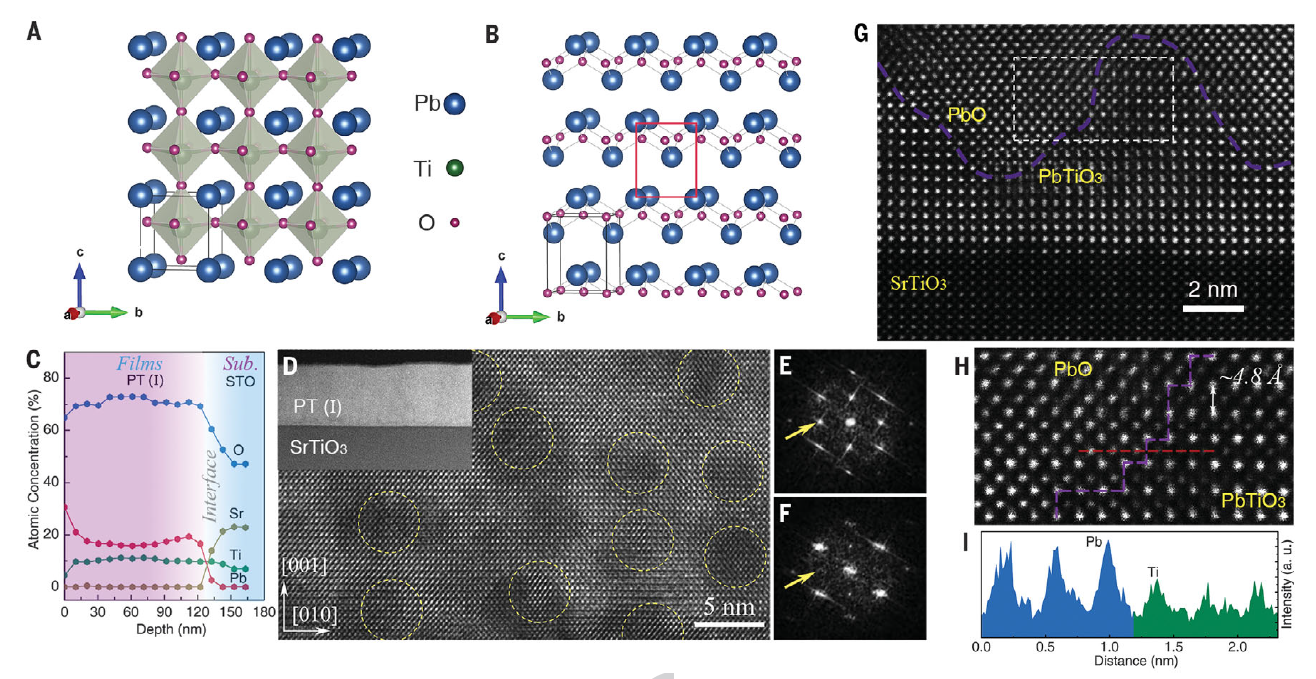

On the basis of material lattice strain engineering, a new phase interface method for adjusting lattice strain is proposed. When two materials of same crystal structure but different lattice constants grow into an epitaxial thin film with a single lattice constant, the lattices of the two materials inevitably undergo a mutual strain adjustment. The physical and chemical properties of functional materials depend on the lattice changes, and hence controlling material lattice strain can help modify the physical and chemical properties of the materials. This technique can be widely used in the fields of ferroelectrics, superconductors, giant magnetoresistance, and catalysis. The rich properties of ferroelectric materials use the basic functional genes of ferroelectric polarization (Fig. 2). Our team has realized the idea of forming an epitaxial thin film of matching lattice with PbTiO3 ferroelectrics and PbO non-ferroelectrics that have different lattice parameters on a SrTiO3 substrate. This method increased the lattice distortion of PbTiO3 to c/a = 1.238 and the residual polarization in the film to as high as 236.3 μC/cm2, which is nearly twice the highest value of any known ferroelectric. In summary, this “phase interface strain” method provides a new avenue for designing ferroelectrics with adjustable polarization genes and can also be applied to the design of other multifunctional materials. Related research results are published in Science [2018, 361(6401):494–497].

Fig.2 Preparation of giant polarized functional ferroelectrics with adjustable polarization genes through “phase interface strain”